One of the first things you learn when working with raw materials is that there's really no such thing as a single, universal "standard sheet." What's considered standard for one material in one country can be completely different for another. The dimensions for length, width, and even thickness are tied directly to the material type and regional practices.

For instance, someone in a steel fabrication shop will talk about sheet measurements in terms of gauge, while a home goods buyer talks about bed sheets in sizes like Queen or King—which themselves vary from country to country.

Decoding Standard Sheet Measurements

The term "standard sheet" is a classic source of confusion, and it all comes down to context. Are you a contractor ordering plywood, a fabricator buying steel, or just trying to get the right fitted sheet for your bed? The definition of "standard" shifts with each scenario. Getting a handle on these differences is the key to avoiding frustration and expensive ordering mistakes.

Every sheet, regardless of material, is defined by three core measurements:

- Length: This is the longest side of the sheet.

- Width: The shorter side, measured perpendicular to the length.

- Thickness: How thick the material is. For metals, this is often called "gauge," while for plastics or wood, it's typically measured in inches or millimeters.

So why isn't there a one-size-fits-all standard? It's a mix of historical measurement systems (think imperial vs. metric) and the unique demands of different industries. In North America, a 4' x 8' sheet of plywood is a construction staple. Take that same measurement to a European supplier, where the metric system rules, and you'll likely get a blank stare.

Why Material and Location Matter

Let’s look at a practical example. An automotive plant needs high-strength steel sheets for car frames. They order based on a specific gauge number, where a lower number means a thicker, more robust metal. For them, standard sheet measurements are dictated by strict engineering specs for performance and safety.

Now, head over to a department store. They stock bed sheets labeled as Twin, Queen, and King. These sizes are set by mattress manufacturers and can be wildly different between countries. A King-size sheet from the United States won't fit a UK King bed correctly. They're just not the same.

Key Takeaway: The idea of a single "standard sheet" is a myth. The correct dimensions are always relative to the material, its intended use, and the geographical region.

This guide will break down the common standards for different materials. Think of it as your cheat sheet for sourcing and selecting the right size for your project, every time.

To help you get a quick overview, here's a reference table summarizing some common sheet dimensions you'll encounter.

Common Sheet Dimensions at a Glance

| Material Type | Common Standard (North America) | Common Standard (International/Metric) | Primary Application |

|---|---|---|---|

| Plywood/Drywall | 4 ft x 8 ft (1220 mm x 2440 mm) | 1200 mm x 2400 mm | Construction, building |

| Acrylic/Plexiglass | 48 in x 96 in (4' x 8') | 2050 mm x 3050 mm (approx. 6.7' x 10') | Signage, displays, fabrication |

| Sheet Metal (Steel) | 48 in x 120 in (4' x 10') | 1000 mm x 2000 mm, 1250 mm x 2500 mm | Automotive, manufacturing |

| Bed Linens (Queen) | 60 in x 80 in (mattress) | 152 cm x 203 cm | Bedding, home goods |

| Bed Linens (King) | 76 in x 80 in (mattress) | 183 cm x 203 cm (UK Super King is similar) | Bedding, home goods |

Keep in mind this table is a starting point. Always double-check the exact dimensions with your supplier before placing an order, especially for projects with tight tolerances.

Navigating Sheet Metal Gauges and Sizes

If you're new to working with industrial materials, you'll quickly learn that sheet metal is a cornerstone of modern manufacturing. It's everywhere, from car frames to architectural panels. But before you can use it, you have to understand its sizing system, and that starts with the concept of gauge.

The first thing to get straight is a rule that seems backward at first: the lower the gauge number, the thicker and stronger the sheet metal. This means a 10-gauge steel sheet is much beefier and more durable than a 22-gauge sheet. The term comes from an old-school method where a wire's gauge was determined by how many times it was drawn through a die to make it thinner. More draws meant a higher number and a thinner wire.

This is a critical distinction in any industry where the material's integrity is a top priority. A car manufacturer, for instance, needs a very specific, thick gauge of high-strength steel for a vehicle's safety cage. A roofer, on the other hand, might opt for a higher-gauge (thinner) galvanized steel for flashing because it’s easier to bend and shape.

How Different Metals Affect Standard Sizes

To add another layer, not all metals use the same gauge scale. Because materials like steel, aluminum, and copper have different densities and properties, their standard sheet measurements and gauge systems vary. You can't assume a 16-gauge steel sheet is the same thickness as a 16-gauge aluminum one—they're different.

- Steel Sheets: The workhorses of construction and fabrication. You'll typically find them in standard sizes like 48 x 96 inches (4' x 8') or 48 x 120 inches (4' x 10').

- Aluminum Sheets: Common in similar large formats, but also widely available in smaller sheets. This makes it a great choice for lighter jobs like custom signage or decorative work.

- Copper Sheets: Prized for its looks, conductivity, and resistance to corrosion. It's often sold by weight in large rolls or in specific pre-cut sizes for things like roofing, electrical components, or plumbing.

Having these standard sizes is what makes the industry go 'round. It creates a predictable supply chain, helps shops minimize waste, and keeps production moving smoothly.

The global sheet metal market is a massive industry, valued at around USD 339.78 billion, and it runs on these standards. In mass production for the automotive, aerospace, and construction sectors, common metric widths of 1,000 mm to 2,000 mm are absolutely essential. For a deeper dive into market trends, check out this detailed market report.

Getting a handle on the gauge system and knowing the typical dimensions for different metals is a fundamental skill. It’s what ensures you choose the right material with the right strength and size for your project, saving you from expensive mistakes down the line.

Understanding Plastic Sheet and Film Dimensions

When you step away from metals and into the world of polymers, you'll find a whole new set of rules for standard sheet measurements. Materials like acrylic, polycarbonate, and PVC each have their own sizing conventions, which are incredibly important across industries from retail display manufacturing to heavy industrial applications.

For a lot of builders and fabricators, plastics are often sold in familiar imperial sizes. The classic 4-foot by 8-foot (4'x8') sheet is a staple, making it a straightforward swap for plywood in many projects. But here’s a tip: always double-check the thickness. It can be listed in either inches or millimeters, and mixing them up can derail a project quickly.

Where Plastic Sheet Standards Really Matter

You can see why these standards are so crucial when you look at real-world projects. Think about creating a sleek retail sign. You'd need an acrylic sheet with a very specific thickness and dimension to slide perfectly into a display frame.

Or, picture a manufacturing plant where tough polycarbonate sheets serve as machine guards. In that scenario, the measurements have to be exact to guarantee worker safety. It’s not just about convenience; it's about reliable performance and safety. While plastic sizing might feel less complex than metal gauges, getting it right is just as vital.

The global market for plastic films and sheets was valued at USD 138.5 billion and is expected to keep growing. To satisfy demand in packaging, automotive, and construction, these materials are often made in standard roll widths from 500 mm to over 2,000 mm. You can dig deeper into this expanding market with this comprehensive market analysis.

Thin plastic films, the kind you see everywhere in packaging, add another layer to the conversation. With films, it’s all about roll width and length. These dimensions are standardized so they can feed directly into automated packaging machinery, which is essential for keeping supply chains running smoothly.

This idea of material standards isn't limited to industrial goods, either. It even applies to textiles. Take bedding, for instance—the material's properties and feel are just as important as the final size. You can see how this works by reading our guide on choosing the perfect bamboo sheet sets.

Why Do Bed Sheet Sizes Seem So Confusing?

Ever bought "King" size sheets online, only to wrestle them onto your bed and realize they don't even come close to fitting? It's a surprisingly common experience. The problem is that standard sheet measurements aren't actually standard worldwide. What one country calls a "Queen" can be a completely different size in another.

These sizing quirks come down to different mattress manufacturing habits and even cultural bedding preferences from one region to the next. For instance, a US "King" is wider and shorter than a UK "King." In fact, the UK "King" is much closer to what someone in the US would call a "Queen." It’s enough to make you second-guess any international purchase.

It's All About the Numbers, Not the Name

The labels we use—Twin, Double, Queen, King—are just that: labels. The actual dimensions are what matter, and they can vary quite a bit. A standard US Queen mattress measures 60 x 80 inches. An Australian Queen, however, is 153 x 203 cm, which works out to be slightly wider and a hair shorter. That tiny difference is all it takes for a fitted sheet to be either baggy or impossible to stretch over the corners.

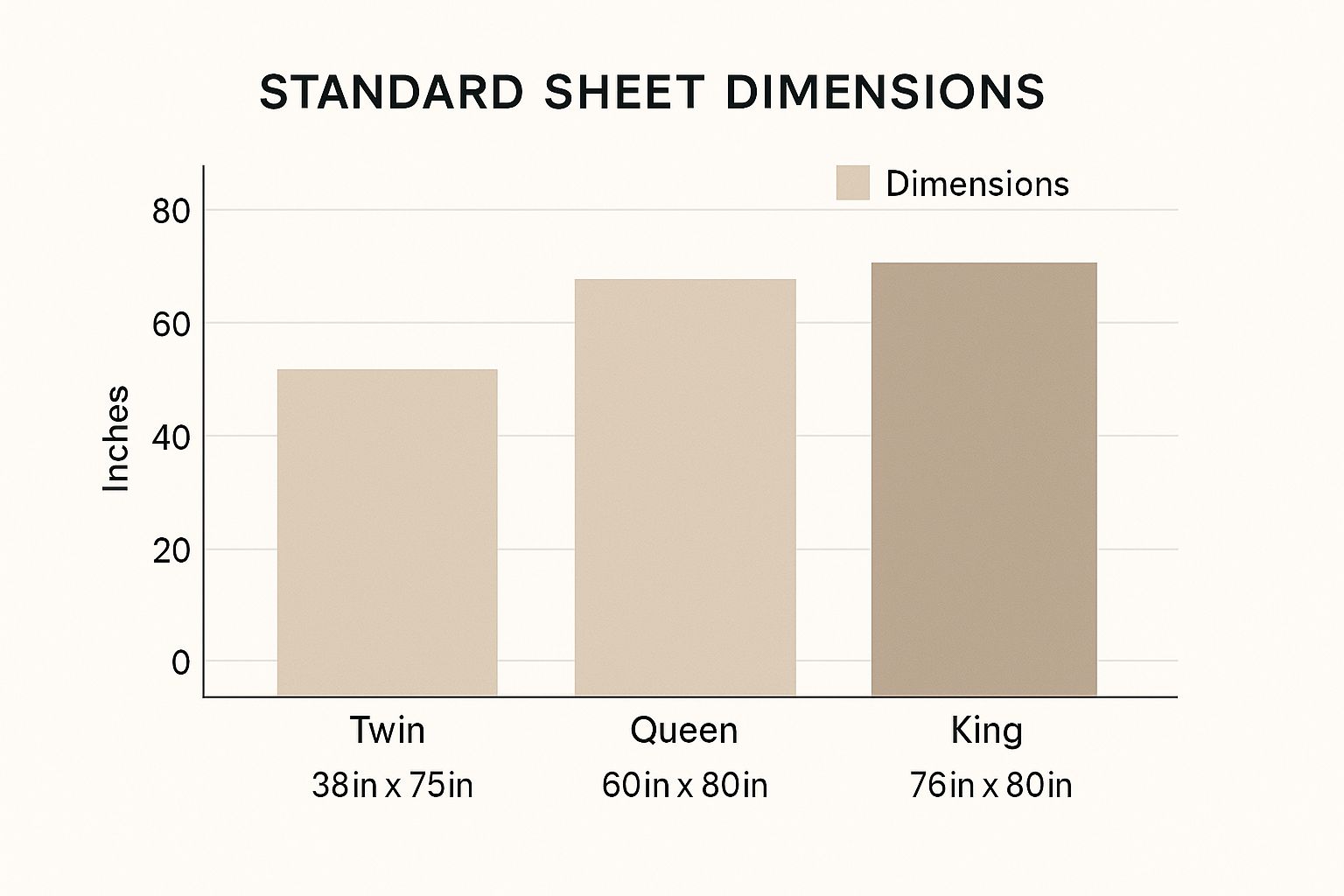

This chart breaks down the common North American sheet sizes so you can see the differences.

As you can see, the biggest jump is in width when you go from a Queen to a King, while the length stays the same.

A Quick Global Comparison

To make sense of it all, it helps to see the numbers side-by-side. The names might be similar, but the measurements tell the real story.

International Bed Sheet Size Comparison Chart

| Bed Size | North America (inches) | United Kingdom (cm) | Europe (cm) | Australia (cm) |

|---|---|---|---|---|

| Twin/Single | 39 x 75 | 90 x 190 | 90 x 200 | 91 x 193 |

| Queen/Double | 60 x 80 | 135 x 190 | 140 x 200 | 153 x 203 |

| King | 76 x 80 | 150 x 200 | 160 x 200 | 183 x 203 |

This table shows just how much things can differ. A King in the UK is significantly smaller than a King in North America or Australia.

How to Get the Right Fit, Every Time

To save yourself the headache of returns, always trust the tape measure, not the name on the package. This is especially true if you're exploring different materials and want to understand what is bamboo sheets, as the fabric's properties can affect the overall fit.

My number one tip? Always, always measure your mattress before you shop. And don't forget the depth! A plush, 15-inch deep mattress needs a totally different fitted sheet than a slim 10-inch one, even if they're both "Queen" size.

Here’s a simple checklist to run through before you click "buy":

- Get Your Mattress Dimensions: Write down the length, width, and—most importantly—the depth. Remember to include any mattress toppers in your depth measurement.

- Read the Product Specs: Hunt for the dimensions listed in inches or centimeters on the product page. Ignore the size name for a moment and focus on the numbers.

- Consider the Source: If you're buying from an international brand, try to confirm which country's sizing standard they're using.

By putting the measurements first, you can shop with confidence, knowing your new sheets will give you that perfect, snug fit you’re looking for—no matter where in the world they come from.

How to Measure for Sheets Accurately

Knowing the standard dimensions is a great start, but nothing beats taking your own measurements to guarantee a perfect fit. Whether you’re working with industrial materials or just making your bed, a little precision goes a long way in saving you time and frustration.

In an industrial setting, for instance, accuracy is everything. When you're measuring something like sheet metal, a tape measure just won't cut it. You'll want to use digital calipers to get a truly precise reading. I always make it a habit to take measurements from a few different spots on the material to ensure the thickness is consistent all the way across.

You also have to remember to account for kerf—that tiny bit of material that gets vaporized or cut away by a saw blade or laser. It might only be a few millimeters, but ignoring the kerf can completely derail a project that relies on tight tolerances.

Measuring for Bed Sheets at Home

Thankfully, things are a bit simpler when measuring for bed sheets, but getting it right is just as important for a well-made bed. The single most common mistake I see is people forgetting to measure the depth of their mattress. That new, plush pillow-top you bought is going to need a much deeper fitted sheet than a standard, slim mattress.

Here's how to get it right every single time:

- First, strip the bed completely. You want to measure the bare mattress, so take everything off, including any mattress protectors or toppers for now.

- Next, measure the length and width. Grab a tape measure and run it from the top edge of the mattress down to the bottom for the length. Then, measure from side to side for the width.

- Finally, measure the depth. This is the crucial part. Place your tape measure at the bottom edge of the mattress and measure up to the very highest point of its top surface. If you use a mattress topper, put it back on and include it in your final depth measurement.

Pro Tip: I always recommend buying a fitted sheet with a "pocket depth" that's at least two inches deeper than your mattress. That extra fabric is what allows the sheet to wrap securely underneath, preventing those annoying corners from popping off in the middle of the night.

Nailing these three simple measurements is the secret to finding a sheet that fits like a glove. For a deeper dive into sizing, you can explore our complete guide to standard fitted sheet sizes.

Common Questions About Sheet Measurements

Walking through the world of sheet sizes can feel surprisingly complicated. You'd think a "King" would be a "King" everywhere, right? Well, not exactly. Let's clear up a couple of the most common questions I hear all the time.

What Is Pocket Depth on a Fitted Sheet?

Ever wrestled with a fitted sheet that just won't stay put? The culprit is almost always the pocket depth.

Simply put, the pocket depth is the corner measurement of a fitted sheet, from the seam down to the elastic edge. This number tells you the thickest mattress it can handle. Standard pockets usually hover around 12 inches, but with today's pillow-top and hybrid mattresses, you'll often see deep-pocket sheets ranging from 15 to 18 inches.

Here's a pro tip: always choose a pocket depth that's at least two inches deeper than your mattress. That extra room allows the sheet to wrap securely underneath the mattress, so it won’t pop off every time you roll over.

Why Don't My King Sheets Fit My King Bed?

This is a classic problem, and it almost always comes down to geography. A "King" bed in the United States (76 x 80 inches) is a completely different size than a "King" in the United Kingdom (60 x 78 inches). In fact, a UK King is much closer to a US Queen.

Key Takeaway: Bed size names like "Queen" or "King" are just labels, not universal standards. To guarantee a perfect fit, especially when buying online or from international sellers, you have to ignore the name and compare the actual length and width measurements to your own mattress.

Ready for the ultimate in comfort and a fit that actually works? Bamtek Home offers 100% organic bamboo sheets with generous 18-inch pockets, ensuring they stay put on even the plushest mattresses. You can experience the difference for yourself.